Perforated plate standard screen

Friday December-20 2024 15:23:54

perforated plate standard screen, also known as a perforated plate sieve, is a type of screening equipment commonly used in various industries for particle size analysis and material separation. This equipment consists of a perforated plate with uniform holes or slots that allow particles of a specific size to pass through while retaining larger particles.

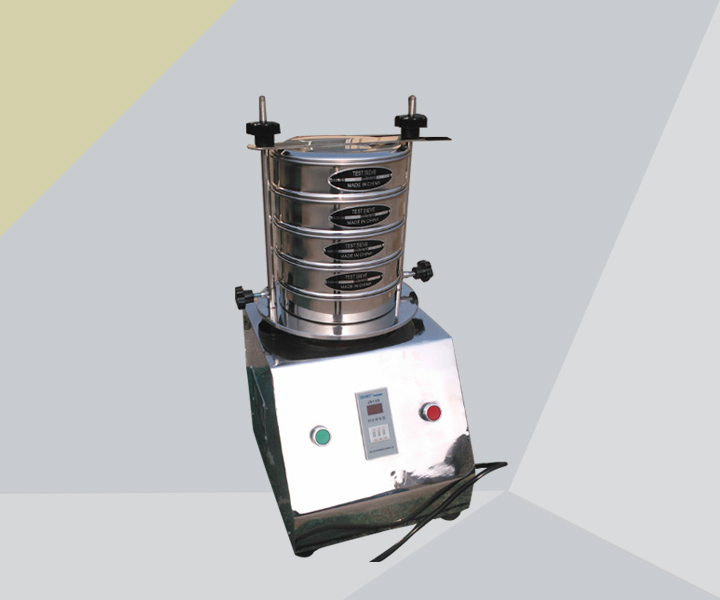

Perforated plate standard screen Structure and Components

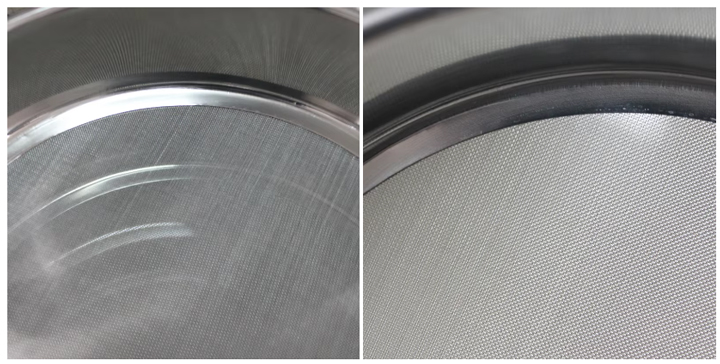

Perforated Plate: The main component of the standard screen is a perforated plate with evenly spaced holes or slots of predetermined sizes. The plate is typically made of metal or other durable materials.

Support Frame: The perforated plate is mounted within a support frame that provides stability and support during the screening process.

Pan or Tray: Beneath the perforated plate, there is a pan or tray to collect the particles that pass through the plate.

Vibration Mechanism: Some perforated plate standard screens are equipped with a vibration mechanism that helps to facilitate the movement of particles through the perforations.

Drive Unit: The drive unit provides the necessary power to operate the vibration mechanism, typically using an electric motor or other power source.

Control Panel: A control panel allows operators to adjust the vibration intensity and other parameters for efficient particle size analysis.

Perforated plate standard screenWorking Principle

The working principle of the perforated plate standard screen is to use the exciting force generated by the vibration motor to vibrate the screen surface. The material gradually moves forward along the screen surface under the action of gravity and vibration force. The larger material is blocked above the screen, and the smaller material falls into the lower layer through the screen hole, thereby realizing the screening of the material.

Perforated plate standard screen Applications

Quality Control: Used for particle size analysis and quality testing of materials in various industries.

Research and Development: Essential for conducting research on particle size distribution and material characterization.

Particle Separation: Employed for separating particles based on size in industrial processes.

Material Classification: Utilized for classifying materials into different size fractions for further processing.

The perforated plate standard screen is a valuable screening tool for particle size analysis and material separation in industries where accurate particle sizing is crucial. Its customizable design, efficiency, and durability make it an essential instrument for quality control, research, and production processes requiring precise particle size analysis and material classification.

Do you want to know the output? model? price? Please click (inside product page) or online consultation to learn more.

Dahan can also customize it for you according to your needs. Come and get the design that suits you.

Kon Leung, Ph.D.

Staff Simulation Engineer at BISSELL Homecare, Inc.