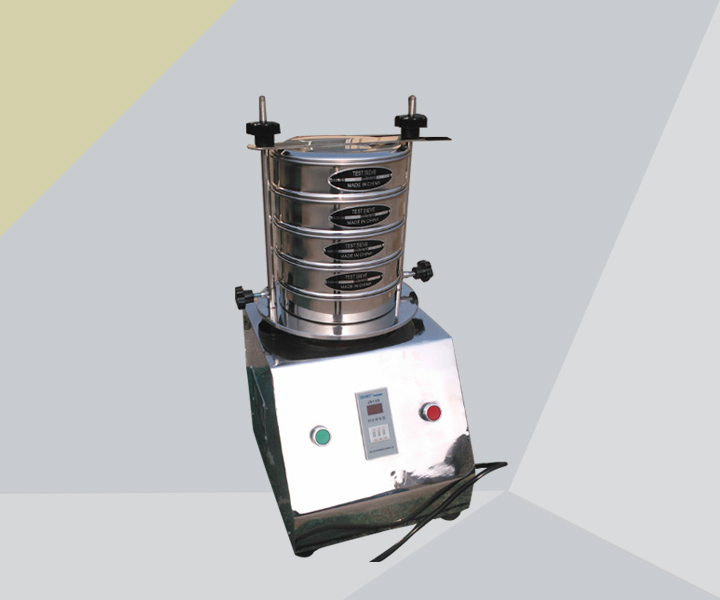

Sieve Shakers for Particle Sizing Analysis

Monday December-09 2024 16:10:33

Sieve shakers are essential laboratory equipment used for particle sizing analysis in various industries, including pharmaceuticals, food processing, construction materials, and environmental monitoring. These devices play a crucial role in determining the particle size distribution of granular materials, powders, and aggregates, which is vital for quality control, research, and process optimization.

Sieve Shakers for Particle Sizing Analysis Function and Importance

Particle Size Analysis: The primary function of sieve shakers is to separate particles into different size fractions using a series of stacked sieves with varying mesh sizes. This enables the determination of the particle size distribution of a sample.

Quality Control: Sieve shakers are used in quality control processes to ensure that materials meet specified particle size requirements, which is critical for product performance and consistency.

Research and Development: In research settings, sieve shakers are employed to study the properties of materials, investigate particle size effects, and develop new products or processes.

Process Optimization: By providing information on particle size distribution, sieve shakers help optimize manufacturing processes, improve product quality, and enhance efficiency.

Sieve Shakers for Particle Sizing Analysis Working Principle

The working principle of a sieve shaker involves subjecting a sample to mechanical vibration or oscillation, causing the particles to move and pass through the openings of the sieves. Here is an overview of the working principle:

Sample Loading: The sample to be analyzed is placed on the top sieve of the stack, with the finest sieve at the bottom to collect the smallest particles.

Vibration: The sieve shaker applies mechanical agitation, typically in the form of vertical or horizontal oscillations, to the sieves. This motion causes the particles to move and pass through the sieve openings.

Separation: As the particles move across the sieves, they are sorted based on size, with larger particles retained on the upper sieves and smaller particles passing through to the lower sieves.

Analysis: After the sieving process is complete, the weight of material retained on each sieve is measured to determine the particle size distribution of the sample.

Sieve Shakers for Particle Sizing Analysis Types of Sieve Shakers

Rotary Sieve Shakers: These shakers use rotary motion to agitate the sieves, providing efficient particle separation for a wide range of materials.

Orbital Sieve Shakers: Orbital shakers combine rotary and tapping motions to enhance sieving performance and reproducibility.

Digital Sieve Shakers: These modern shakers feature digital controls for precise adjustment of vibration intensity and duration, improving accuracy in particle size analysis.

Sieve Shakers for Particle Sizing Analysis Advantages of Sieve Shakers

Accuracy: Sieve shakers provide accurate and reliable results in particle size analysis, essential for quality control and research applications.

Reproducibility: By standardizing the sieving process, these devices ensure consistent and reproducible particle size data.

Efficiency: Sieve shakers automate the sieving process, saving time and labor compared to manual sieving methods.

Versatility: They can be used with a wide range of sieve sizes and materials, making them suitable for diverse applications.

Sieve Shakers for Particle Sizing Analysis Applications of Sieve Shakers

Pharmaceutical Industry: Used for analyzing particle size distribution of active ingredients, excipients, and powders in drug formulations.

Food Processing: Employed in the food industry to assess the particle size of ingredients, additives, and food products.

Construction Materials: Used for quality control in the production of aggregates, cement, and building materials.

Environmental Monitoring: Utilized in environmental studies to analyze soil samples, sediments, and particulate matter.

Sieve shakers are indispensable tools for particle sizing analysis in various industries, providing valuable insights into the particle size distribution of materials. By enabling accurate and reproducible sieving results, these devices support quality control, research, and process optimization efforts, contributing to improved product quality, efficiency, and innovation in diverse applications.

Do you want to know the output? model? price? Please click (inside product page) or online consultation to learn more.

Dahan can also customize it for you according to your needs. Come and get the design that suits you.

Kon Leung, Ph.D.

Staff Simulation Engineer at BISSELL Homecare, Inc.