What is a mechanical shaker?

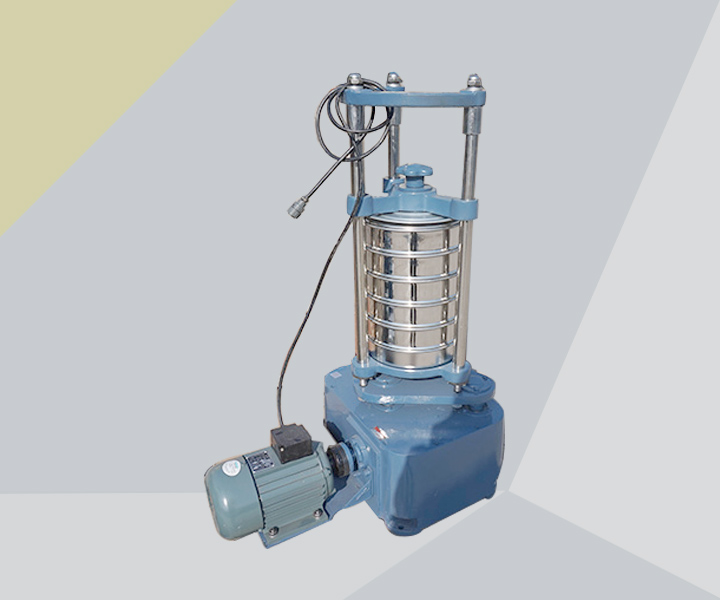

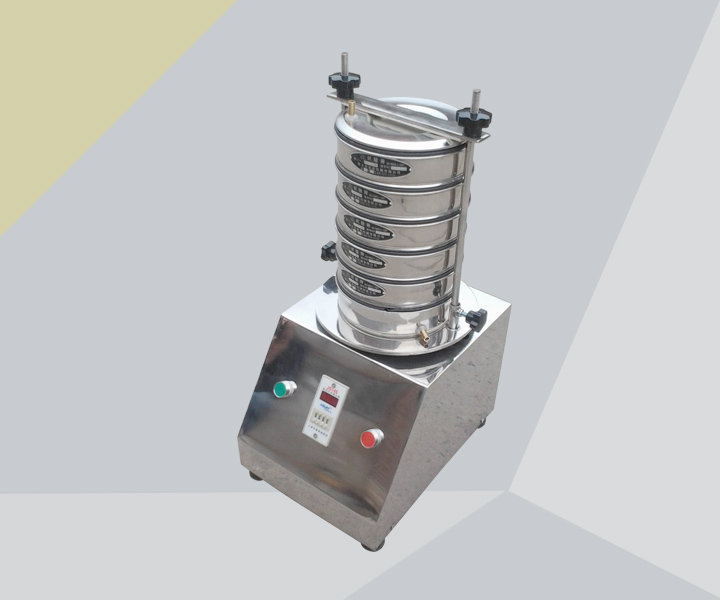

Mechanical sieve is a screening equipment used in conjunction with test sieves, and can be used for standard sieves with a diameter of 200MM and 300MM. The top impact standard vibrating screen machine is mainly composed of a swing mechanism, a shock mechanism, a clamping mechanism and other parts. It performs screening work through circumferential swing and up and down vibration. The screening time can be set according to the needs. It is suitable for roads, Laboratories of construction, geological and metallurgical scientific research departments conduct screening and analysis of materials.

Mechanical Sieve Function

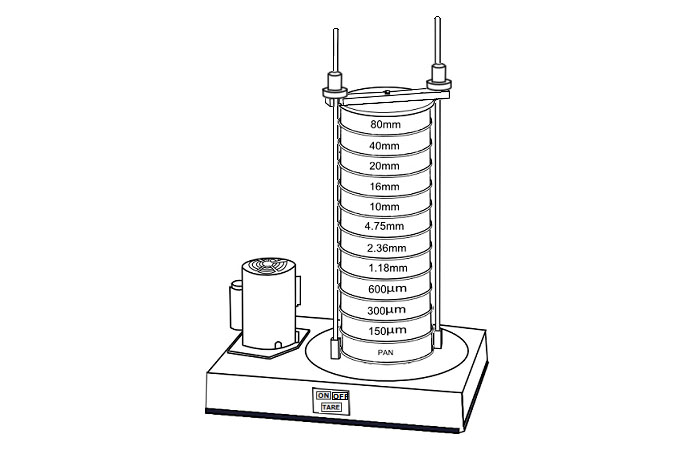

1. It has dual motions of rotation and vibrating. The screening work is carried out through circumferential swing and up and down vibrating. The feeding is faster, which can reduce material clogging and improve screening accuracy.

2. The sieving time can be controlled regularly to ensure the repeatability of the experiment and the accuracy of the sieving data.

3. 8 layers of test sieves (including the bottom of the sieve) can be placed, and a granular material can be precisely separated into 2-7 particle size segments at the same time.

4. The standard vibrating sieve machine is the equipment used in conjunction with the test sieve. It can clamp the Φ200 test sieve, and can also install the Φ75 and Φ100 sets of sieves.

Mechanical Sieve Applications

Mechanical Sieve is mainly used in scientific research units in the fields of coal power, electric power, mining, geology, chemical industry, metallurgy, building materials, chemical industry, etc., and material screening and analysis in college laboratories. It is equipped with an independent control box, and the working time of the vibrating sieve can be set arbitrarily. , the timing range is 0-99 minutes, it is a laboratory sieving instrument that replaces manual sieving and reduces the labor intensity of the operator.

How Mechanical Sieve works?

The motor rotates through the rotating shaft and the main eccentric shaft on the swing frame of the worm gear auxiliary belt, which in turn drives the other two auxiliary eccentric shafts to rotate, so that the swing radius of the entire screen group is also equal to the plane circle swing of the eccentricity. At the same time, the same motor drives another pair of worm gears to pass through the cam, and the swing frame with the screen group is installed on the ejector rod, which periodically lifts up and falls on the anvil of the machine base by its own weight, so that the swing frame can vibrate while swinging in a plane circle. hit.

Product Structrue

| hommer | mandril | eccentric wheel | motor |

| motor gear | synchronous belt | tray | bottom slider |

| cabinets |

Mechanical Sieve is mainly composed of machine base, upper cover, rotary structure, shock mechanism, clamping mechanism and sieve sleeve.

1. Slewing mechanism: The motor and pinion mounted on the upper box drive the dual gears and gears to rotate, and the main eccentric shaft rotates at the same time, causing the secondary eccentric shaft of the oscillating disk to swing with a radius of 12.5, which is driven by the support rod, etc. The sieve tray and sieve are rotated and shaken synchronously.

2. Topping mechanism: While the machine’s slewing mechanism is moving, the key installed on the swing plate shaft cover drives the upper camshaft to rotate; due to the speed difference between the upper protruding shaft and the lower camshaft, the upper end of the upper camshaft is effectively , hitting the sieve tray etc. for up and down movement 147 times per minute.

3. Clamping mechanism: When the sieve is installed on the machine, turn the knob clockwise, and the cone nut will move upward along the axial direction. ) into the knob hole and tightened to achieve the purpose of reliably fixing the sieve cover; turn the knob in the opposite direction to loosen it.

4. Appearance material: cast iron base, spray green paint, cast iron table, fixed steel rod.

5. Power part: electric motor with capacitor.

6. Vibration and jacking parts: eccentric wheel, spring, swing plate shaft, upper protruding shaft and lower camshaft.

FAQ

Pls provide the following information for us.

1. screen machine

2. screen frame(200mm,300mm)

3.quantity

4. the size of the screen mesh

5. Do you want FOB/CIF?If you choose the CIF,please tell me the port of destination

6.How many layers you need?

7. Pls inform the voltage&frequency in your city.

8.the other special request.

RELATED INDUSTRIES

MAIN TECHNICAL PARAMETERS:

| Serial number | Name | Unit | Numerical |

| 1 | Sieve diameter | cm | 20 |

| 2 | Matchable sieve layers number | Layer | 7 |

| 3 | Sieve aperture | mm | 0-0.038 |

| 4 | Shake times | Time|Minute | 221 |

| 5 | Hit times | Time|Minute | 147 |

| 6 | Turning radius | mm | 12.5 |

| 7 | Top striking distance | mm | 10mm |

| 8 | Motor power | kw | 0.38 |

| 9 | Power voltage | v | 380 |

| 10 | Motor speed | Turn|Minute | 2800 |

| 11 | Machine weight | Thousand Jin | 120 |

| 12 | Outline dimension | mm | 586*370*952 |