Key Factors Affecting Soil Experimental Screening

Monday January-17 2022 15:37:23

1:Appropriate Particle Size Range

The closer the particle size of the material is to the demarcation diameter, the more difficult it is to separate.

2:Water Content

With the increase of moisture content and viscosity in the material, it is easy to agglomerate or block the sieve hole.

3:Material Attributes

The shape and surface state of particles are irregular, and the materials with small density are not easy to sieve.

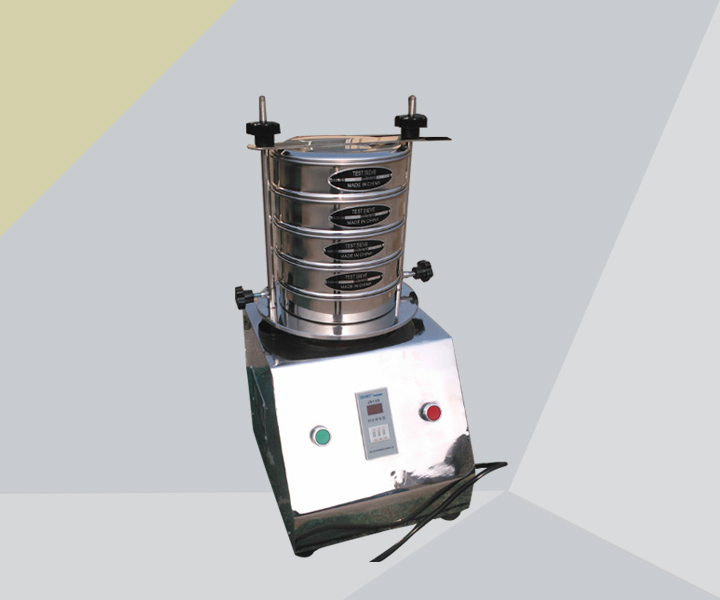

4:Parameters Of Screening Device

For example, how to make screen:

1.Eye-Punching Screen

Also known as die sieve, tied to the metal plate punched out of the circular sieve hole. Its sieve hole is strong and not easy to deform. It is mostly used for screening coarse particles such as sieve plate and pills of high-speed rotary mill.

2.Braided Screen

It is made of metal wires with certain mechanical strength (such as stainless steel, copper wire, iron wire, etc.) or other non-metallic wires (such as silk, nylon wire, silk, etc.). The advantages of braided sieve are many sieve holes per unit area and high screening efficiency, which can be used for fine powder screening. The screen made of non-metal has certain elasticity and durability. Nylon yarn is stable to general drugs and is widely used in pharmaceutical production. However, the displacement of braided sieve yarn easily leads to the deformation of sieve hole and the decrease of separation efficiency.

Solid Powder Classification

Coarsest Powder, Coarsest Powder, Medium Powder, Fine Powder, Finest Powder, Extremely Fine Powder

Coarsest Powder - refers to the powder that can pass through the first sieve, but not more than 20% of the powder can pass through the third sieve.

Coarse Powder - refers to the powder that can pass through sieve No. 2, but not more than 40% through sieve No. 4.

Medium powder - refers to the powder that can pass through sieve No. 4, but not more than 60% through sieve No. 5.

Fine powder - refers to the powder that can pass through sieve No. 5 and contains not less than 95% of the powder that can pass through sieve No. 6.

Finest powder - refers to the powder that can pass through sieve 6 and contains not less than 95% of the powder that can pass through sieve 7.

Very fine powder - refers to the powder that can pass through sieve 8 and contains not less than 95% of the powder that can pass through sieve 9.

Do you want to know the output? model? price? Please click (inside product page) or online consultation to learn more.

Dahan can also customize it for you according to your needs. Come and get the design that suits you.

Kon Leung, Ph.D.

Staff Simulation Engineer at BISSELL Homecare, Inc.