Composition

| Frame | stainless steel plate, low-carbon plate, wood plate |

| Mesh Shape | square hole, round hole, diamond hole |

| Mesh | stainless steel mesh,galvanized wire mesh, nylon wire mesh, chrome plate, stainless steel plate, galvanized plate, copper plate, wood plate, aluminium alloy plate, plastic plate |

Sieve Shaker Machine Application

Sieve shaker machine is used in scientific research and production departments, laboratories, quality inspection rooms of metallurgy, chemical industry, medicine, building materials, geology, national defense and other industries, aiming at the particle size structure, liquid solid content and sundries of granular and powdery materials Perform vibration sieving, filtration and standard test testing.

The specific industries are as follows:

Food industry: corn, starch, flour, salt, soybean milk, fruit juice, beverage

Pharmaceutical industry: traditional Chinese medicinal materials, western medicine granules, industrial pharmaceuticals, traditional Chinese medicine powder, pills, etc.

Chemical industry: chemical fertilizer, petroleum coke, resin, paint, paint, metal powder, quartz sand, etc.

Metallurgical industry: aluminum powder, copper powder, alloy powder, electromagnetic materials, refractory materials, alumina, etc.

Other industries: cosmetics, plastics, abrasives, papermaking, additives, activated carbon, carbon, etc.

RELATED INDUSTRIES

Sieve Shaker Machine Classification

1. Metal woven mesh standard screen

Diameter: 200mm, 75mm, 300mm, mesh number: 0.02mm~2.36mm, implementation standard: GB/T6003.1-1997 (equivalent to ISO3310.1).

2. Metal perforated plate standard sieve

Plate mesh screen for short, diameter: 200mm, 300mm, mesh size: 1mm~125mm, implementation standard: GB/T6003.2-1997 (equivalent to ISO3310.2).

3. Electroforming standard sieve

Diameter 75mm, 200mm, mesh: 5um~500um, implementation standard: GB/T6003.3-1999 (equivalent to ISO3310.3).

Sieve Shaker Machine Advantages

With one-time stamping forming

The screen frame is smooth

No leakage

Low noise, noise less than 75 decibels

High yield, up to 5 times the output per unit area;

Small acceleration, long service life of components, no leakage;

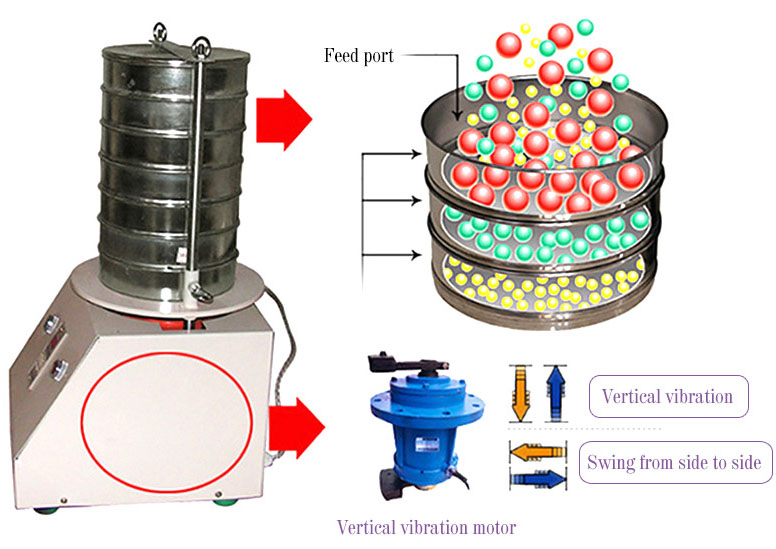

Sieve Shaker Machine Principle

After the Sieve shaker machine is started, the YZU vertical vibration motor is used as the vibration source, and the vibration motor drives the upper vibration plate to vibrate, and then conducts the vibration through the vibration plate to the screen frame placed on the upper part of the vibration plate. The material particles are screened to the lower sieve frame, so that only the same particle size materials are left in each layer of the sieve frame, so as to achieve the separation of different particle sizes and determine the particle size composition of the material, so that the materials in the sieve frame can be used for filtering, grading and screening purposes.

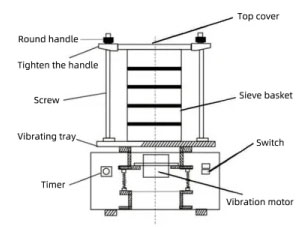

Sieve Shaker Machine Diagram

Sieve shaker machine is mainly composed of top cover, round handle, clamping handle, screw, screen frame, vibration tray, timer, switch, vibration motor and so on.

MAIN TECHNICAL PARAMETERS

| Screen size | Diameter(mm) | Mesh | Granularity (μm) |

| No.1 | 200 | 10 meshes | 2000±70μm |

| No.2 | 200 | 24 meshes | 850±29μm |

| No.3 | 200 | 50 meshes | 355±13μm |

| No.4 | 200 | 65 meshes | 250±9.9μm |

| No.5 | 200 | 80 meshes | 180±7.6μm |

| No.6 | 200 | 100 meshes | 150±6.6μm |

| No.7 | 200 | 120 meshes | 125±5.8μm |

| No.8 | 200 | 150 meshes | 90±4.6μm |

| No.9 | 200 | 200 meshes | 75±4.1μm |