What is a Standard test sieve?

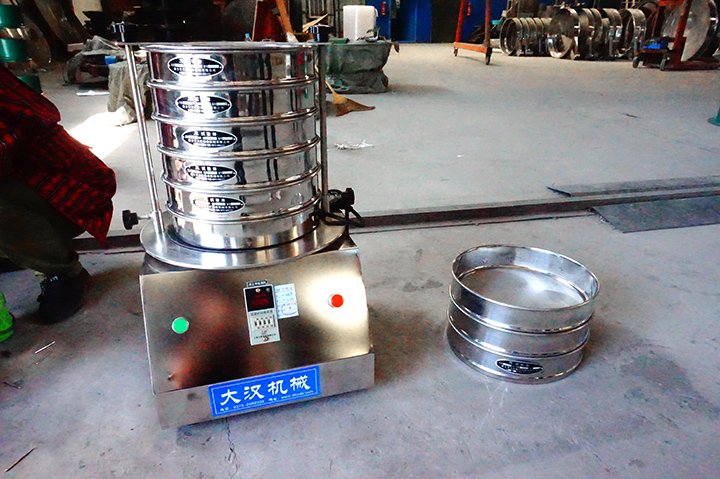

Standard test sieve is a tool for particle size classification and particle size detection of material particles. The sieve size is 500μm-5μm, and there are strict mesh size regulations. The test sieve uses the mesh size to represent the specifications of each sieve. It is a sieve that is inspected, identified, and deemed to be in compliance with the agreement by a designated agency. A set of 37 standard screens, including 12 wire woven mesh screens. It consists of screen frame, screen cover, screen bottom, and is made of stainless steel. The materials include ordinary iron sheet, stainless steel, copper screen frame, etc. The screen mesh includes nylon mesh, stainless steel mesh, copper mesh, metal perforated plate, etc.

Standard test sieve classification

1. Metal braided mesh Standard test sieve

Diameter: 200mm, 75mm, 300mm, mesh number: 0.02mm~2.36mm, implementation standard: GB/T6003.1-1997 (equivalent to ISO3310.1).

2. Metal punching plate Standard test sieve

Plate mesh screen for short, diameter: 200mm, 300mm, mesh size: 1mm~125mm, implementation standard: GB/T6003.2-1997 (equivalent to ISO3310.2).

3. Electroforming Standard test sieve

Diameter 75mm, 200mm, mesh: 5um~500um, implementation standard: GB/T6003.3-1999 (equivalent to ISO3310.3).

Standard Test Sieve Specifications

| name | application | Specification |

| Standard Soil Sieve | Analyze the particle size distribution of the soil, allowing the separation of soils of different fineness | 0.075mm, 0.25mm, 0.5mm, 1mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 13mm, 20mm, 40mm, 60mm |

| standard gravel screen | Determination of sand, silt and clay | 2.5, 5, 10, 16, 20, 25, 31.5, 40, 50, 63, 80, 100mm, with bottom cover or 2.36, 4.75, 9.5, 16, 19, 26.5, 31.5, 37.5, 53, 63, 75, 90mm, with bottom cover |

| Standard Pharmacopoeia Screening | Analysis and detection of powder, drug and granule | 10mesh, 24mesh, 50mesh, 65mesh, 80mesh, 100mesh, 120mesh, 150mesh, 200mesh |

| stone standard sieve | For determining the particle size distribution of sand, aggregates, soils | 1、1.7、2.5、3.15、5、7.1、10、16、20、25、35.5、40、45、56、63mm |

| cement standard sieve | Check the fineness of cement | A total of 5 pieces, including the bottom cover, the specifications are 0.125, 0.71, 0.9, 5, 20mm |

| Standard sieve for aggregate | Determine aggregate particle size distribution | 80、60、50、40、30、25、20、10、5、2、1、0.5、0.2、0.075mm |

Advantages of Standard Test Sieve

1. It is made of SUS304 stainless steel stretched and polished, with a wall thickness of 0.6mm, uniform luster, strong and durable, and non-magnetic;

2. Accurate screening accuracy and high efficiency, and can screen to 0.025-3mm;

3. Equipped with time relay control, the inspection time is not bad in minutes and seconds;

4. The ingenious base shock-absorbing design can effectively shield the vibration of the equipment on the workbench during operation and reduce the working noise;

5. The screen mesh and the screen frame are fixed by soldering to prevent loosening and shaking, and can work stably at a temperature >300 degrees;

6. The whole machine is exquisite in design, reliable in quality, light in weight, small in size, and convenient to place and move.

Standard test sieve application

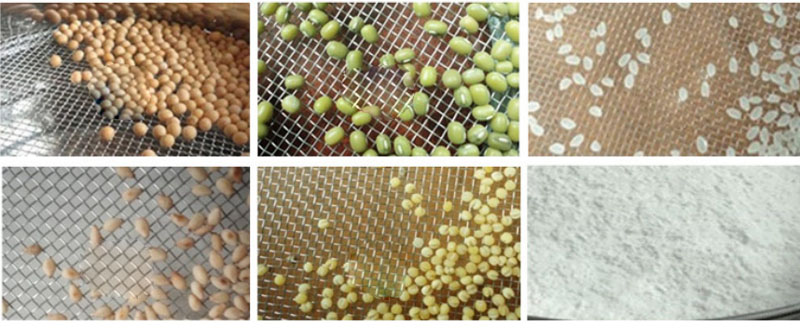

Standard test sieve is widely used in scientific research and production departments, laboratories, and quality inspection rooms in metallurgy, chemical industry, medicine, building materials, geology, national defense and other industries. It is aimed at the particle size structure, liquid solid content and sundries of granular and powdery materials Vibration sieving, filtration and standard test testing.

The specific industries are as follows:

Food industry: corn, starch, flour, salt, soybean milk, fruit juice, beverage

Pharmaceutical industry: traditional Chinese medicinal materials, western medicine granules, industrial pharmaceuticals, traditional Chinese medicine powder, pills, etc.

Chemical industry: chemical fertilizer, petroleum coke, resin, paint, paint, metal powder, quartz sand, etc.

Metallurgical industry: aluminum powder, copper powder, alloy powder, electromagnetic materials, refractory materials, alumina, etc.

Other industries: cosmetics, plastics, abrasives, papermaking, additives, activated carbon, carbon, etc.

RELATED INDUSTRIES

MAIN TECHNICAL PARAMETERS

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 | ||

| Stainless steel sieve specifications, if you need special specifications, you can contact online customer service consultation. | |||||||