Composition

| Frame | stainless steel plate, low-carbon plate, wood plate |

| Mesh Shape | square hole, round hole, diamond hole |

| Mesh | stainless steel mesh,galvanized wire mesh, nylon wire mesh, chrome plate, stainless steel plate, galvanized plate, copper plate, wood plate, aluminium alloy plate, plastic plate |

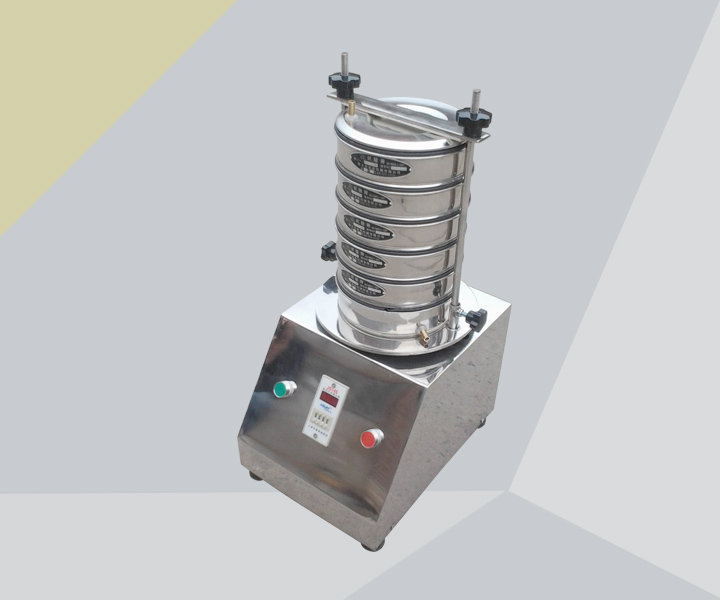

What is a Laboratory sieve shaker?

Laboratory sieve shaker, also called Laboratory sieve shaker machine, is mainly used in the laboratory for the standard inspection of granular and powdery materials, particle size structure, liquid solid content and sundry content, screening, filtering, testing, etc. It can be automatically shut down at regular intervals , can precisely separate a kind of granular material into 2~7 particle segments at the same time.

What is a Laboratory Sieve Shaker Used for?

Laboratory sieve shaker is widely used in scientific research and production departments, laboratories, and quality inspection rooms in metallurgy, chemical industry, medicine, building materials, geology, national defense and other industries. It is aimed at the particle size structure, liquid solid content and sundries of granular and powdery materials Vibration sieving, filtration and standard test testing.

RELATED INDUSTRIES

Laboratory sieve shaker Features

1. The screen frame is made of SUS304 (0Cr18ni9) stainless steel stretched and polished, the wall thickness is 0.6mm, the surface is smooth, and the overall shape is strong and durable, without magnetism. The screen mesh and the screen frame are fixed by soldering without loosening. Can withstand high temperature below 300 degrees.

2. The mesh is precise, because the mesh is marked according to the mesh, so the meshes of the same specification produced at different times are consistent.

3. It can be installed and used in multiple layers, and can divide a material into 2-7 different particle segments at the same time.

MAIN TECHNICAL PARAMETERS

| Screen size | Diameter(mm) | Mesh | Granularity (μm) |

| No.1 | 200 | 10 meshes | 2000±70μm |

| No.2 | 200 | 24 meshes | 850±29μm |

| No.3 | 200 | 50 meshes | 355±13μm |

| No.4 | 200 | 65 meshes | 250±9.9μm |

| No.5 | 200 | 80 meshes | 180±7.6μm |

| No.6 | 200 | 100 meshes | 150±6.6μm |

| No.7 | 200 | 120 meshes | 125±5.8μm |

| No.8 | 200 | 150 meshes | 90±4.6μm |

| No.9 | 200 | 200 meshes | 75±4.1μm |

Laboratory Sieve Shaker Manufacturers