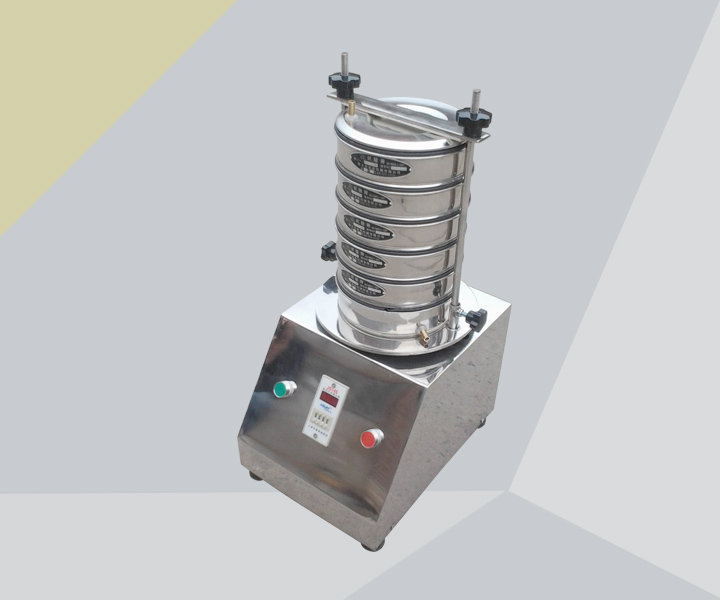

What is an ultrasonic sieve shaker?

Ultrasonic Sieve Shaker adds ultrasonic sieving system on the basis of ordinary test sieve. It is a special equipment for fine powder detection. It has higher and more accurate detection accuracy and can effectively solve the problems of strong adsorption, easy caking, high static electricity, high density, light Specific gravity and other materials. The problem of mesh blockage caused by sieving; the mesh is not blocked by continuously changing the ultrasonic frequency to excite the screen. Ultrasonic sieve shaker is equipped with a time relay, which can realize timing from 0 to 99 minutes, and automatic shutdown at timing to ensure standardization of detection. The whole machine is polished with 304/316L stainless steel, anti-corrosion, high temperature resistance of 200 degrees, non-magnetic, and can be used for fine detection and classification of 600-mesh fine powder.

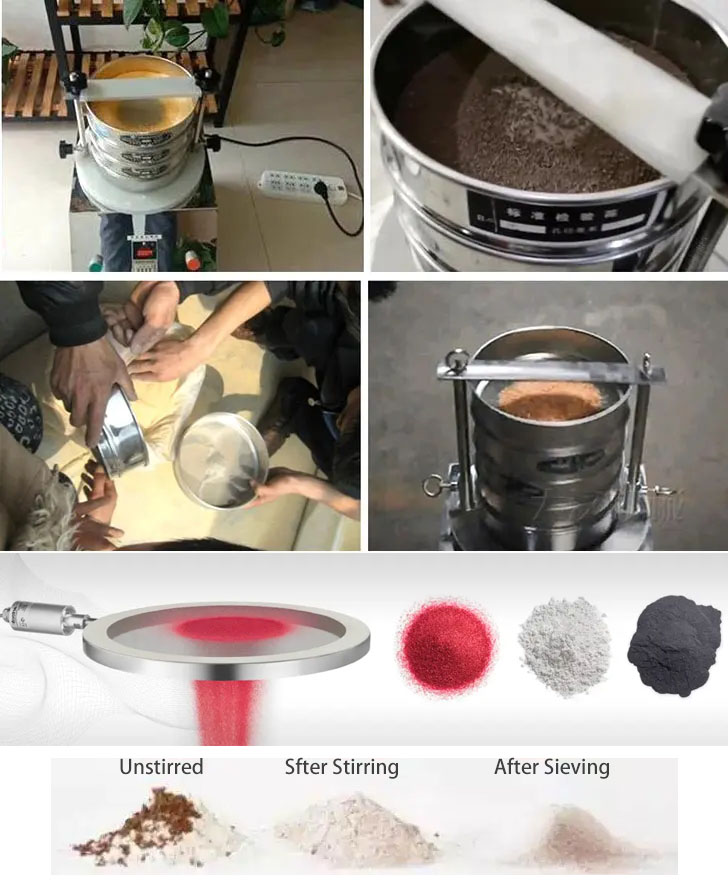

Ultrasonic sieve shaker videos

-

Calcium Hydroxide Detection

Screening mesh: 200 mesh, 300 mesh, 400, 500 mesh

Recommended: diameter 200mm

-

Filter western medicine powder

Screening mesh: 300 mesh

Recommended: diameter 300mm

-

Sieve graphite powder

Screening mesh: 30、40、60 mesh

Recommended: diameter 100mm

Ultrasonic sieve shaker Application

Ultrasonic sieve shaker can be used to sieve and detect fine powder materials within 600 meshes. It is commonly used in scientific research and production, laboratories, quality inspection rooms and laboratories of colleges and universities. Specific materials include: medicine powder, gown powder, electromagnetic powder, metal powder, flour , pigment or powder coating, coal slime, crystalline material, diamond, graphite powder, spices, abrasives, soil samples, plastic powder, cement powder or ceramic mixture, calcium carbonate powder, etc.

Ultrasonic sieve shaker Feature

1. The ultrasonic screening device is added, the inspection accuracy is higher and more accurate, and the laboratory screening problems due to agglomeration, static electricity, and strong adsorption blocking the mesh are solved.

2. High screening precision, can screen to 0.025-3mm.

3. The screen frame of the ultrasonic test sieve is made of 304 stainless steel stretched and polished, non-magnetic, corrosion-resistant, clean and hygienic.

4. The screening time can be controlled by the time relay, and it can be shut down at regular intervals to ensure the consistency of each production or test.

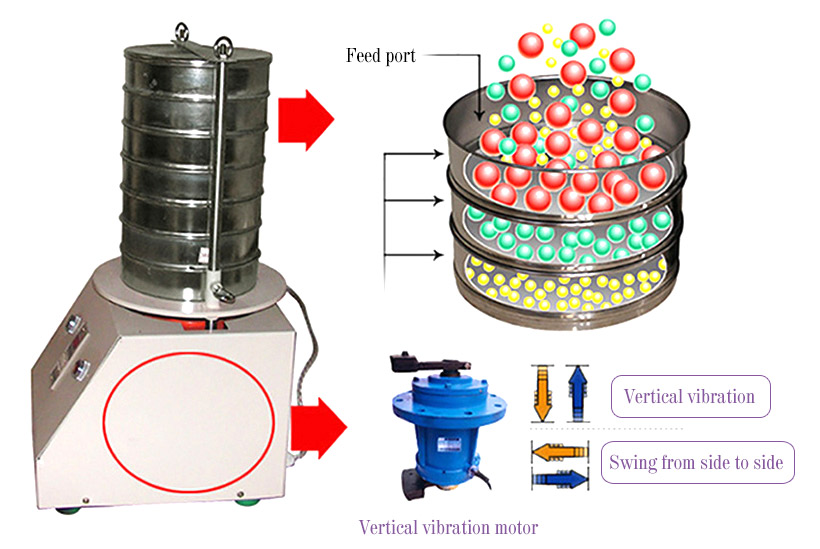

How does the Ultrasonic Sieve Shaker work?

After the Ultrasonic sieve shaker starts, it relies on the converter to convert ordinary electric energy into high-frequency electric energy, and then converts it into a high-frequency sinusoidal oscillation wave by the oscillator. The oscillator transmits the oscillation wave evenly to the screen surface, and the materials on the screen surface are affected The force is uniform, while the low-frequency three-dimensional vibration is performed on the screen surface, ultrasonic vibration is superimposed, and the material screening efficiency is high and the effect is good.

Ultrasonic sieve shaker technical parameters

| serial number | name | unit | data | |

| 1 | Standard sieve body | layer | 1-8 layers | |

| 2 | Screen diameter | mm | φ200 | |

| 3 | Screening size | mm | 0.038-3 | |

| 4 | noise | dB | ≤50 | |

| 5 | Feeding amount (one time) | g | ≤200 | |

| 6 | amplitude | mm | ≤5 | |

| 7 | time control | min | 1-60 | |

| 8 | Adapt to material | powder/granule | ||

| 9 | mode of operation | 3D motion | ||

| 10 | control mode | Memory storage 1-9 screening programs | ||

| 11 | display mode | digital display | ||

| 12 | motor | Voltage | V | 220 |

| 13 | Rotating speed | r/min | 1420 | |

| 14 | power | KW | 0.08 | |

| 15 | Machine quality | Kg | 38 | |

| 16 | Dimensions | mm | 400×350×650 | |

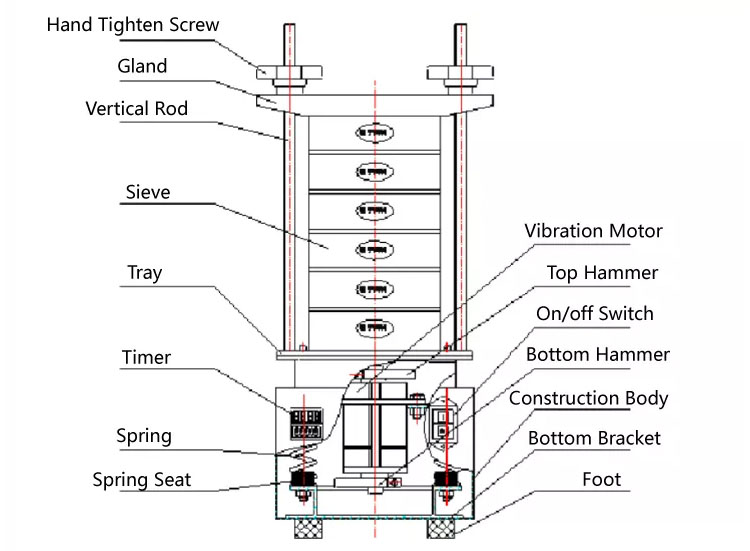

Ultrasonic Sieve Shaker Structure

Ultrasonic sieve shaker is mainly composed of host (standard test sieve), ultrasonic vibration power supply, test sieve frame, high-frequency connecting wire, connector, oscillator and so on.

Ultrasonic power supply: Built-in microcomputer chip, which can automatically track the whole digital frequency according to the different states of the ultrasonic wave. Power input: AC 220V±10%, machine current ≤0.6A, high-frequency current ≤0.5A, working frequency 30KHz, working mode continuous, pulse, ambient temperature -10~40℃.

Test sieve frame: There are 2 kinds of diameters: 200mm and 300mm, 200mm is the general type. There are also some customers who need 75 mm as special requirements. The screens have different mesh sizes from 8 mesh to 500 mesh. There are 2 types of screens according to the number of meshes: perforated plate and woven mesh.

Time relay: It is a control appliance that uses electromagnetic principles or mechanical principles to achieve time-delay control.

High-frequency connection line: the screen frame and the ultrasonic vibration power supply are connected by cables.

Connector: Aviation connection plug-in.

Oscillator: high-performance ultrasonic conversion device.

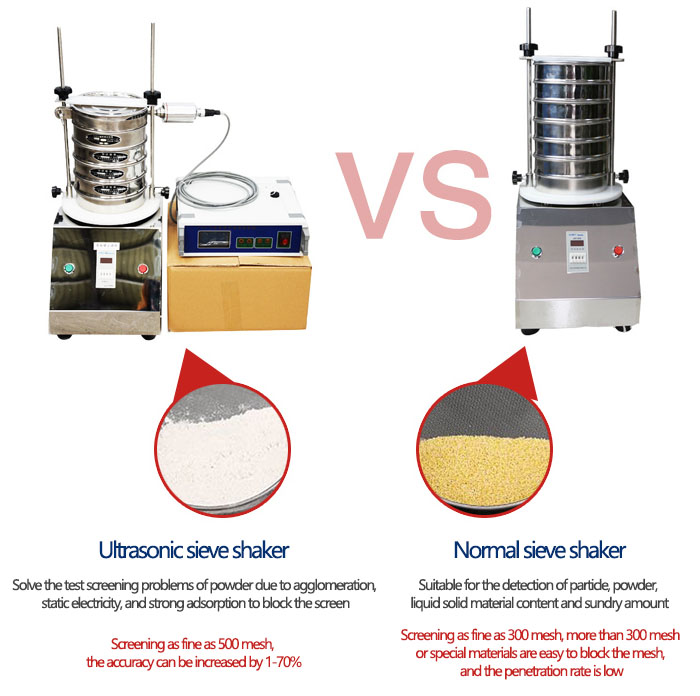

Difference between ultrasonic sieve shaker and normal sieve shaker

Since the transducer on the ultrasonic system of the Ultrasonic sieve shaker directly acts on the grid to control the sieve, the sieving effect will be better than that of the ordinary standard inspection sieve, especially in fine powder screening and detection. Outstanding, the following table lists the differences between these two test sieves for you:

| Comparison item | Ultrasonic sieve shaker | Normal sieve shaker |

| application | Allows separation down to 20 microns (#635 mesh) | 200 mesh or more coarse mesh, more than 200 mesh is easy to block the screen |

| Network congestion | The vibration frequency is 36,000 times/second, which can quickly decompose the attachment, and the passing rate of the screen surface can be increased by 50%-400%, and the screen will not be blocked | During the process of sieving fine powder, it is easy to block the mesh, resulting in accumulation, thereby reducing the output and product quality |

| Cost of production | Screen clogging is eliminated, product quality is consistent throughout production, and there is no downtime to clean screens, reducing the risk of downtime | The screen surface needs to be cleaned after each use. If the screen is blocked during use, it needs to be shut down for investigation, which is costly |

Ultrasonic sieve shaker manufacturers

Dahan Ultrasonic sieve shaker manufacturer produces ultrasonic test sieve (Ultrasonic standard test sieve), stainless steel Ultrasonic sieve shaker, Ultrasonic test sieve, Ultrasonic pharmacopoeia sieve, Ultrasonic soil sieve, Ultrasonic laboratory vibrating sieve, lithium iron phosphate ultrasonic test sieve, chemical dye ultrasonic test The sieve and other products have complete models and specifications, and the price is as low as 500 yuan. The ultrasonic test sieve is a special equipment for the detection and screening of fine powder within 500 meshes. It has high detection accuracy and does not block the sieve. Optional, according to different materials, the factory provides different screening schemes, you can consult according to your needs.

Our Service

We provide 12months quality warranty to make sure your machine well runs consistently.

Pre-sale services:

a.Professional engineer design the production line for you.

b.Recommend suitable equipment according to your special demand.

During-sale services:

a.Precheck and accept products before delivery.

b.Send technicians to the jobsite for guiding the installation and adjustment.

c.Training operators and finishing the check to satisfy your requirement.

After-sale services:

a.Common problem can be solved through web in 24 hours,complex problem can be reacted immediately in 24 hours and solved as soon as possible.

b.To establish long-term friendship,we will regularly contact with our customers.

FAQ

Q:What is the real delivery time of your factory?

A:10 to 15 days for general series products,meanwhile,customized products would need 20 days to 40 days based on different situations.

Q:How do you ensure the quality of your products?

A:Generally,our equipments are the most durable type in the industry,this is also the feature of the label impression of DH for most of our customers at home or abroad.

However,we do recognized that there do have small amount of the product which may got faulty or damaged for different reasons.

Q:How do you after-sale service work if the product got damaged?

A:In the guarantee time 12 months,our general aftersale serve.

Payment support

This supplier also supports L/C,D/A,D/P,T/T,Western Union,MoneyGram payments for offline orders.