What is an ultrasonic sieve shaker?

Saturday November-19 2022 10:49:23

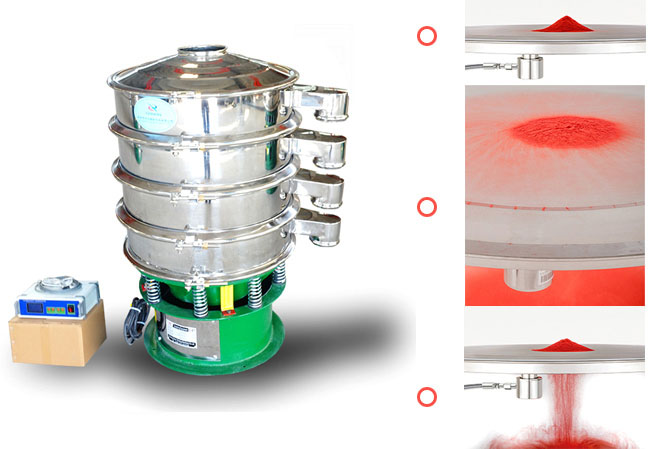

Ultrasonic sieve shaker is an ultrasonic system installed on the basis of the test sieve machine, using ultrasonic frequency to vibrate the mesh, which can prevent the holes from being blocked, and can also screen the powder more easily, and the screening capacity is increased by up to 10 times, while allowing as low as 20 microns (#635 mesh) separation accuracy.

Ultrasonic Sieve Shaker Application

Ultrasonic sieve shaker is designed for on-time micro-powder detection, and is widely used as a test sieve in food, pharmaceutical, chemical, metallurgy, mineral processing and other industries. It has high detection accuracy and no mesh clogging.

How Ultrasonic Sieve Shaker Works

When the Ultrasonic sieve shaker is started, the material on the screen is subjected to low-frequency three-dimensional vibration and superimposed ultrasonic vibration, which can prevent mesh blockage and improve screening output and quality. The additional ultrasonic system can be added to any layer of the experimental sieve, and it is very convenient to install and disassemble.

Ultrasonic Sieve Shaker Features

1. The device has an ultrasonic transducer, which solves the problem of mesh blockage when the laboratory is doing fine powder sampling and screening.

2. The test sieve frame is made of SUS304 (0Cr18ni9) stainless steel stretched and polished, which can withstand high temperature below 300 degrees.

3. It can be installed with 1-8 layers of test sieves (including the bottom of the sieve), and can precisely separate 2~8 particle segments from one kind of granular material at the same time.

4. The inspection and screening time is controlled by a time relay to realize automatic shutdown at regular intervals to ensure test repeatability.