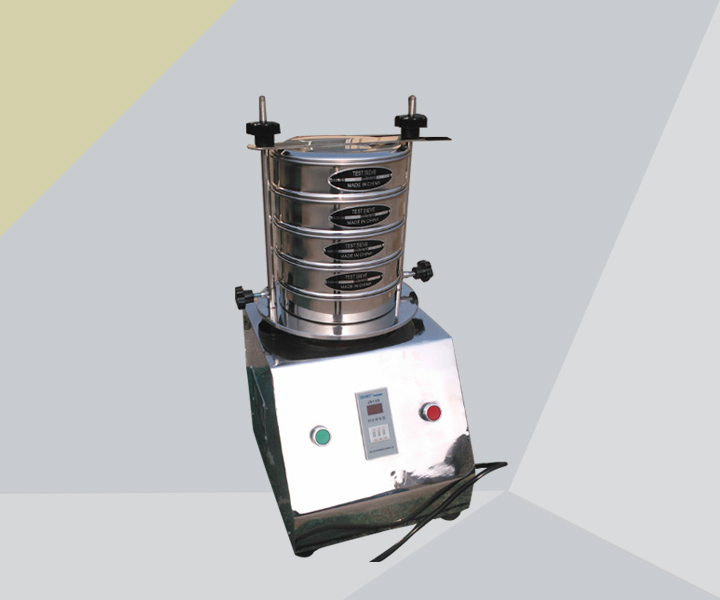

Zinc Dust And Zinc Oxide Screening Machines

Wednesday January-24 2024 09:54:59

Zinc dust and zinc oxide screening machines are equipment used for screening and classifying zinc powder and zinc oxide. They separate particles according to size through the action of vibration, rotation or air flow to achieve particle size classification. These screening machines offer advantages such as efficiency, precision, automation, flexibility and a wide range of applications. They are widely used in electronics, chemical industry, metallurgy and other industries to produce high-quality zinc powder and zinc oxide.

Zinc dust and zinc oxide screening machines Principle

The principle of Zinc dust and zinc oxide screening machines is based on the differences in particle size and shape of materials. Through the screening process, zinc powder and zinc oxide whose particle size meets the requirements are separated to achieve the purpose of particle size classification. The principle of screening can be simply described as: the material is subjected to the vibration force on the screen, causing the particles to move relative to the screen, and particles of different sizes will be separated by the different sizes of the screen holes.

Zinc dust and zinc oxide screening machines Types

Vibrating screening machine: Vibrating screening machine is one of the most commonly used screening equipment. It uses vibration force to cause relative movement of materials on the screen to achieve particle separation. The vibration screening machine has the advantages of high efficiency, reliability and energy saving, and is suitable for screening zinc powder and zinc oxide.

Cyclone screening machine: The cyclone screening machine uses the principle of cyclone screening to separate materials into particles of different sizes through the centrifugal force of rotation. The cyclone screening machine has the characteristics of high efficiency, continuous operation, and not easy to be blocked. It is suitable for subdivided screening of zinc powder and zinc oxide.

Air flow screening machine: Air flow screening machine is a device that uses the action of air flow for screening. Under the action of air flow, the material is separated into particles of different sizes according to the size and density of the particles. The airflow screening machine has the characteristics of high efficiency and no dust pollution, and is suitable for screening fine powder of zinc powder and zinc oxide.

Zinc dust and zinc oxide screening machines process

Feeding: Feed raw zinc powder and zinc oxide into the feeding port of the screening machine.

Screening: In the screening machine, materials are screened through the action of vibration, rotation or air flow to separate particles that meet the requirements.

Classification: According to needs, the screened particles are classified into zinc powder and zinc oxide of different particle sizes.

Collection: Collect and store the separated zinc powder and zinc oxide for subsequent processing or use.

Advantages and applications of Zinc dust and zinc oxide screening machines

Efficiency: The screening machine can efficiently separate zinc powder and zinc oxide to improve production efficiency.

Accuracy: Screening machines can perform particle size classification as needed to ensure product quality and consistency.

Automation: The screening machine can realize automated operation, reduce manpower investment and improve production efficiency.

Flexibility: Different types of screening machines can adapt to different screening requirements and production environments, and have high flexibility.

Zinc powder and zinc oxide screening machines are widely used in electronics, chemical industry, metallurgy and other industries to meet the needs of different fields.

Zinc dust and zinc oxide screening machines play an important role in zinc dust and zinc oxide production. Through reasonable selection and use of screening machines, efficient and precise screening of zinc powder and zinc oxide can be achieved, improving product quality and production efficiency. With the continuous advancement of technology, screening machines will continue to improve and innovate to provide more efficient and intelligent solutions for the screening of zinc powder and zinc oxide.

Do you want to know the output? model? price? Please click (inside product page) or online consultation to learn more.

Dahan can also customize it for you according to your needs. Come and get the design that suits you.

Kon Leung, Ph.D.

Staff Simulation Engineer at BISSELL Homecare, Inc.